- Feed Production Line

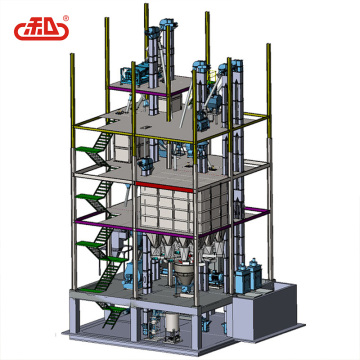

- Feed Pellet Production Line

- Poultry Feed Production Line

- Chicken Feed Production Line

- Pig Feed Production Line

- Cattle Feed Production Line

- Sheep Feed Production Line

- Ruminant Feed Production Line

- Aquatic Feed Production Line

- Pet Feed Production Line

- Pre-mixing Feed Production Line

- Concentrated Feed Production Line

- Biomass Pellet Production Line

- Straw Processing Production Line

- Wood Pellet Production Line

- Bio-fertilizer And Organic Fertilizer Production Line

- Feed Processing Small Unit

- Hammer Mill

- Mixing Equipment

- Pellet Mill

- Extrusion Equipment

- Cooling Equipment

- Feed Crushing Machine

- Sifting Equipment

- Bagging Machine

- Cleaning Equipment

- Dust Collection Equipment

- Batching System

- Oil Adding Sustem

- Conveying Equipment

- Modulation Equipment

- Electric Control System

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.