Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: High Grade Livestock Pellet Feed Production Line

Brand: HEXIE

Type: Pellet Mill

Processing Object: Mixed Feed

Processing Technics: Crushing-before-Mixing

Screen Mesh: With Screen Mesh

Grinding Equipment Type: Feed Hammer Mill

Pellet Mill Type: Ring Die Pelleter

Bulking Machine Type: Twin Screw Bulking Machine

Condition: New

Applicable Materials Shape: Granular

Packaging: Standard Export Wooden Case

Productivity: 3-15TPH

Transportation: Ocean,Land

Place of Origin: CHINA

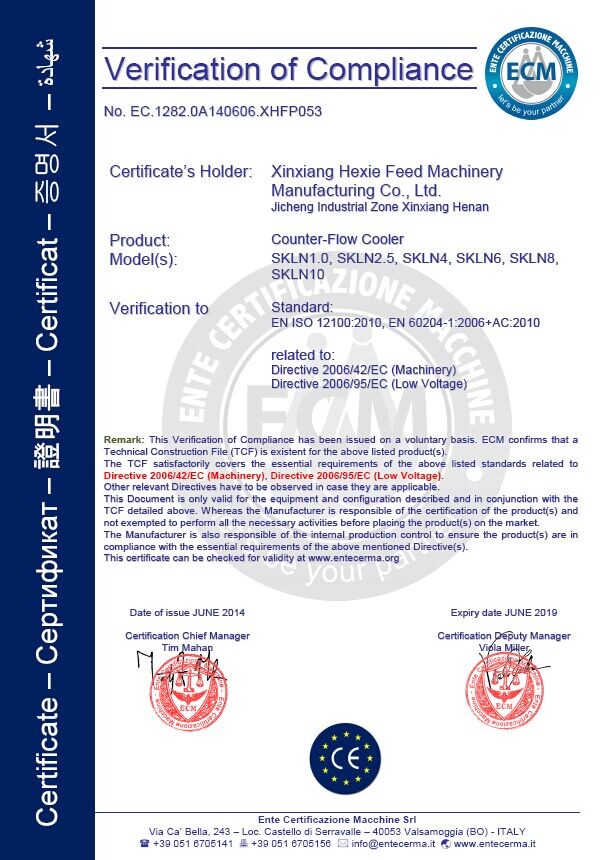

Certificate: ISO9001,CE

HS Code: 84361000

Port: QINGDAO SEAPORT

Payment Type: L/C,T/T,D/P

Incoterm: FOB,CFR,CIF,EXW

Product Categories : Feed Production Line > Feed Pellet Production Line

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.